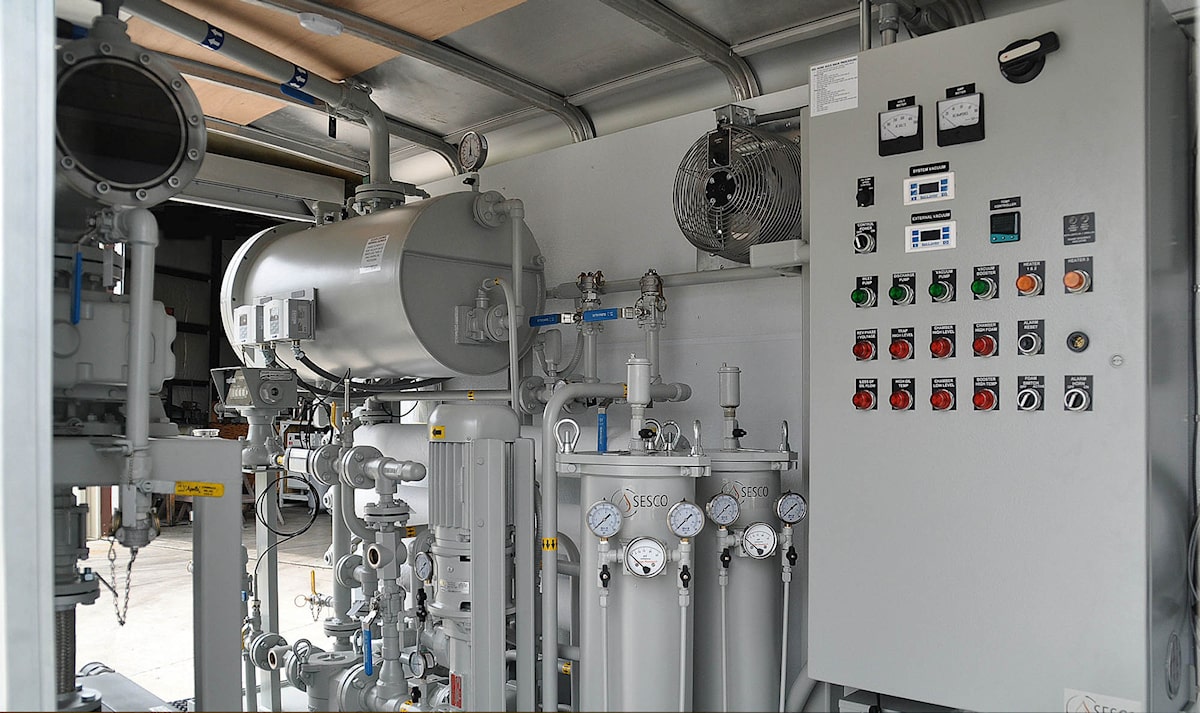

This compact, mobile insulating oil conditioning system is designed for single pass conditioning of new and in service (Group I & II) insulating fluids, increasing voltage values (dielectric strength) by removing dissolved water, dissolved gas, and solid matter contamination. The SES320-600 includes vacuum dry out capabilities and can be used to vacuum filling.

SES320-600 Highlights

Condition Mineral & Natural Ester Fluids

Single Pass Processing

10 GPM (2271 LPH)

64 kW Electric Heating

375 Cfm Vacuum System

Transformer Evacuation

| Mineral Oil | Natural Ester Fluids | |

|---|---|---|

Design Flow Rate | 10 GPM | 2271 LPH | De-rate processing rate and heating capacity by 25% |

| Max Flow Rate | 12 GPM | 2725 LPH | |

Dielectric Strength (2 mm gap) | > 65 kV | > 60 kV |

Moisture Content (ASTM-D1533-88) | 100 ppm reduced to < 10 ppm | 200 ppm reduced to < 30 ppm |

Moisture Content (ASTM-D1533-88) | 100 ppm reduced to < 2 ppm | 200 ppm reduced to < 20 ppm |

Total Gas Content | Saturation reduced to < 0.25% | Saturation reduced to < 0.25% |

| Total Gas Content 3 Passes (ASTM-D2945) | Saturation reduced to < 0.15% | Saturation reduced to < 0.15% |

Particulate Content | 99.9% > 1 μ | 99.8% > 1 μ |

Processing Temperature | Min 170 F° | 76 C° | Min 170 F° | 76 C° |

Processing Vacuum Level | 1.5 - 0.3 Torr | 1.5 - 0.3 Torr |

Typically built to order, the SES321-600 and can be customized to any requirement

Standard Flow Circuit

- Automatic internal recirculation – no valves to adjust

- Automation degas chamber level control

- Discharge pressure is automatically controlled and adjustable to 80 psi

- Discharge adjustable from 0 – 100% of circulation rate

- Built in hose suck back and drain capability

Oil Pumping System

- Two pump systems. Inlet pump standard

- Direct mount low speed positive displacement screw pumps

- Viton mechanical seals

- External relief valves

Electric Heating Systems

- Low watt density heating does not degrade oil

- (2) 32 kW heater banks

- Heater banks can be disabled at the control panel to reduce amperage requirement if necessary

- Digital PID individual bank control scheme provides smooth accurate generator friendly operation

- Oil flow and over temperature safety interlocks provided

Filtration System

- Coarse inlet pump strainer provided

- Dual ASME code filter housings provide two stage particulate filtration. 3 & 0.5 micron

- Pleated synthetic media.

- 99.8% efficiency

- Local dirty filter gauges standard

- Automatic air bleed standard

Degasification System

- Three stage dispersal system

- Single pass performance

- 316 SS chamber shell and interior components

- Automatic non-pilot operated level control system

- Primary dispersing system

- Transparent chamber cover on system

- Safety high level overflow shutdown interlock switch

- Low level warning switch

- Fiber optic foam control system

- Automatic vent

Vacuum System

- Two stage system

- System capacity is sized at 0.5 Torr for 1.25X the maximum oil conditioning vapor load.

- Vacuum system blank off pressure is < 0.05 Torr

- Vacuum systems can be isolated for dedicated transformer evacuation

- 304SS vacuum system piping

- Vacuum booster pump inlet safety oil trap w/ shutdown interlock is provided.

Protects vacuum booster pump from chamber or transformer overflow

- Rotary vane backing vacuum pump

- Direct drive Roots style rotary lobe pump vacuum booster pump

Local Instrumentation

- Inlet Suction Gauge

- Inlet Temperature Gauge

- Filter Inlet & Outlet Gauges

- Dirty Filter Gauges

- Chamber Manifold Vacuum Gauge

- Discharge Pressure Gauge

- Discharge Temperature Gauge

- Flow Rate Meter

- Dual Register Positive Displacement Flow Totaling Meter

Standard Instrumentation

- Inlet Temperature

- Inlet Suction

- Chamber Vacuum

- Aux Vacuum Line Vacuum

- Outlet Pressure

- Outlet Temperature

- Inlet Temperature Control

- Discharge Flow Rate

- Discharge Flow Total

Electrical System

- All control packages are built to NEMA and IEC specifications

- Main Power Disconnect Breaker

- 100% Circuit Breaker Protection

- IEC Motor Starters and Overload Protection

- Circuit Breaker Protected Heater Contactors

- Individually Controlled Banked Heaters

- System Hour Meter

- Vacuum Pump Hour Meter

- Alarm Horn

- Amp Meter

- Phase Indicator

Standard Control System

- A NEMA 4, push button and pilot operator interface is used to provide pump, heating system, and automatic valve control. Pumps, heaters, and automatic valves status by pilot lights. The system incorporates a 7" color operator interface for alarm annunciation, alarm logging, and troubleshooting. Data logging is optional. optional.

HMI Displayed Instrumentation:

- Status & Control Displays:

- All Motors

- All Heater Banks

- All Actuated Valve Positions

- All Alarms

- All Warnings

- Oil Temperature Set Point

- HMI Displayed Instrumentation:

- Inlet Pressure

- Outlet Oil Flow Rate

- Outlet Out Total Gallons

- Outlet Pressure

- Degas Chamber Vacuum Level

- External Vacuum Line Vacuum Level

- Heater Outlet Temperature

Construction

- Skid mounted with a recessed deck plate for drip collection.

- System design facilitates easy access for maintenance and operation.

- Piping

- All oil piping is welded carbon steel w/ butt weld or socket fittings. All vapor and water piping is stainless steel with w/ but weld or socket weld fittings. Maintenance connections use bolted flanges or O-ring sealed unions. Threaded unions are not used. Threaded connections are kept to a minimum.

- Instrumentation Tubing

- Oil filled tubing is 1/4" carbon steel w/ carbon steel compression fittings.

- Electrical Conduit

- A combination of ridged and liquid tight flexible conduit is used to provide a water tight easy maintenance wiring system

Oil Pumping System

- Inlet oil booster pump for evacuated transformer circulation

Filtration System

- Dirty filter alarms

- Oversized inlet housing

Vacuum System

- Fail-safe external vacuum line actuated valve

Instrumentation

- Remote Transformer Vacuum Gauge (760 Torr – 0.01 Torr)

- Inlet Moisture & Temperature Monnitor

- Outlet Moisture & Temperature Moitor

- External Vacuum Line Dew Point Monitor

Control Package

- Data logging

Mobile versrsions of the SES320-600 are typically cargo trailer mounted. Consult factory for options.

Skid Mounting

Built-to-order skid-mounted equipment can normally be built to meet customer footprint and access requirements. Consult SESCO with special requests.Cargo Trailer Mounting

All cargo trailers are specifically engineered to accommodate equipment load, weight distribution, to provide optimum towing conditions. Cargo trailer weight capacities (GVRW) range from 4,000 to 16,000 Lbs. SESCO will provide the cargo trailer size and weight capacity options available for the system being quoted.

Follow