Insulating Oil Purifier

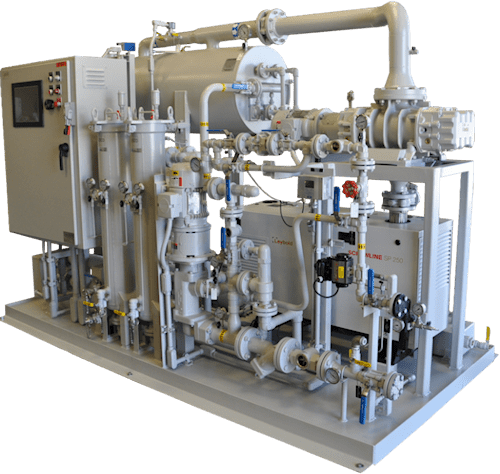

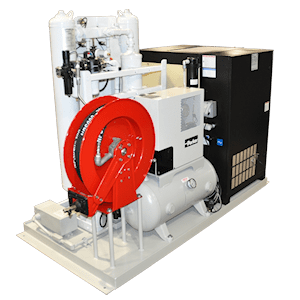

The SES320 insulating oil conditioning and regeneration system is fully customizable and available in stationary and numerous mobile configurations .

Insulating Oil Purifier

The SES320 insulating oil conditioning and regeneration system is fully customizable and available in stationary and numerous mobile configurations .

Insulating Oil Purifier

The SES320 insulating oil conditioning and regeneration system is fully customizable and available in stationary and numerous mobile configurations .

Insulating Oil Purifier

The SES320 insulating oil conditioning and regeneration system is fully customizable and available in stationary and numerous mobile configurations .

Insulating Oil Purifier

The SES320 insulating oil conditioning and regeneration system is fully customizable and available in stationary and numerous mobile configurations .

This compact, mobile insulating oil conditioning system is designed for single pass conditioning of new and in-service (Group I & II) insulating fluids, increasing voltage values (dielectric strength) by removing dissolved water, dissolved gas, and solid matter contamination. The SES320-1200 includes vacuum dry out capabilities and can be used for vacuum filling.

SES320-1200 Highlights

20 GPM/4560 LPM

128 kW Electric Heating (Std)

1200 Cfm Vacuum System (Std)

6.5 PSI Inlet NPSH

70 PSI Discharge Pressure

Treatment Stages

Capabilities

Design Specifications

The SES320 conditioning system uses multiple treatment stages to improves dielectric strength by removing particulate, dissolved water and dissolved gas. The SES320 can also completely regenerate badly degraded mineral oil and remove dissolved sludge during hot oil re-circulation.

The SES320 and accessories provide the tools necessary to efficiently complete all transformer oil processing, maintenance, and dry-out tasks.

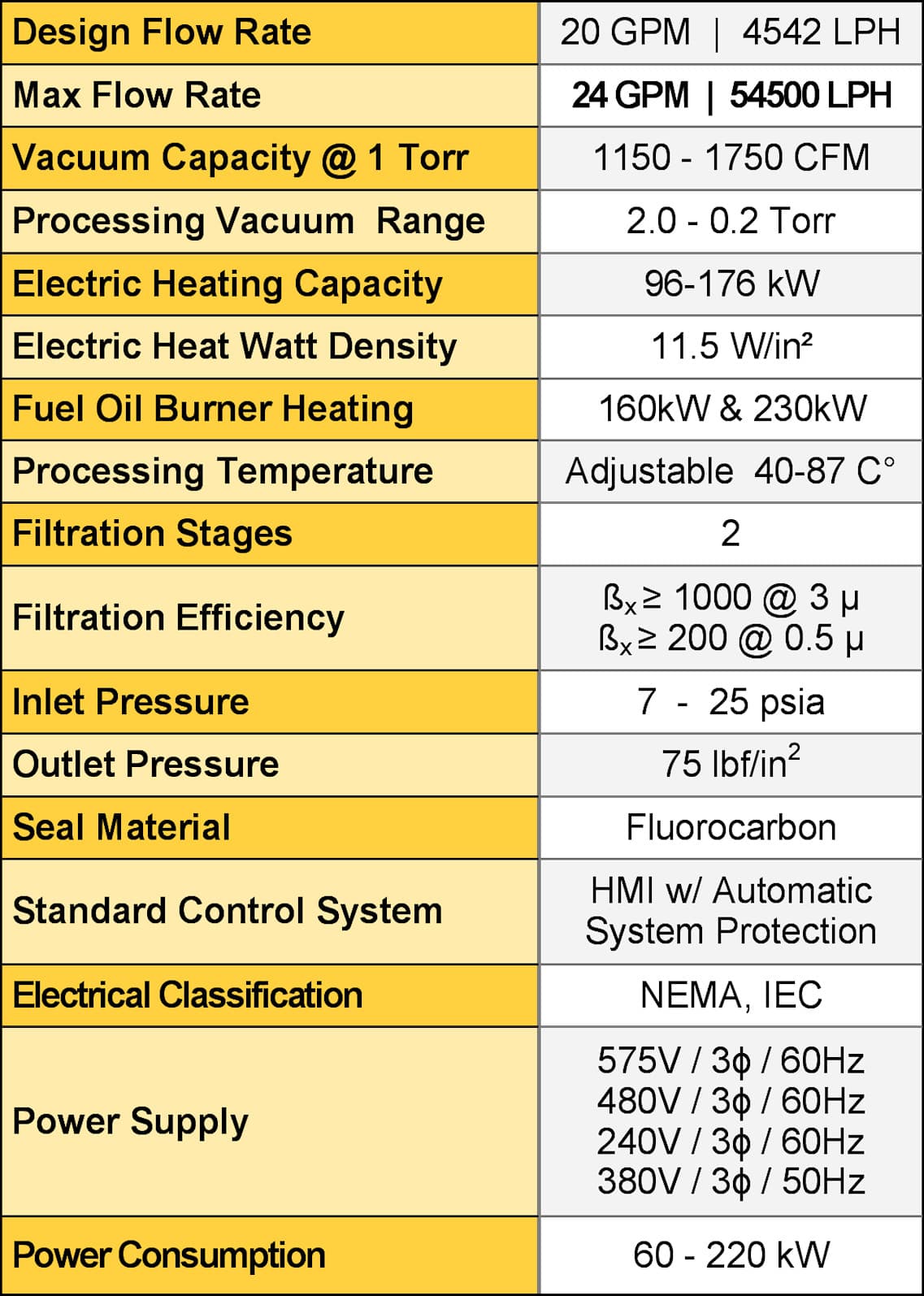

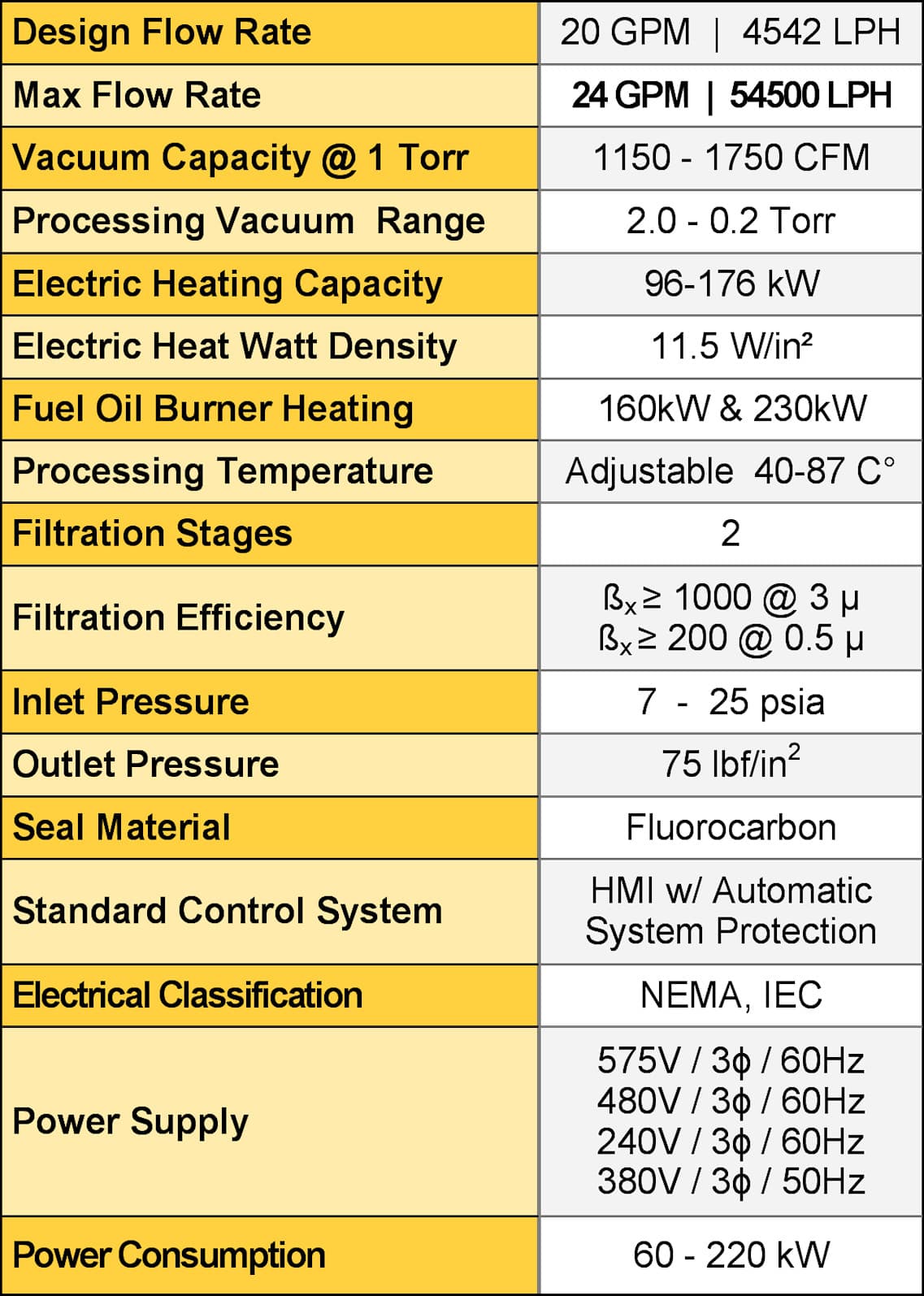

The SES320 insulating oil conditioning and regeneration systems are robustly designed to single pass performance specifications to completely satisfy all possible oil processing requirements.

Treatment Stages

The SES320 conditioning system uses multiple treatment stages to improves dielectric strength by removing particulate, dissolved water and dissolved gas. The SES320R can also completely regenerate badly degraded mineral oil and remove dissolved sludge during hot oil re-circulation.

Capabilities

The SES320(R) and accessories provide the tools necessary to efficiently complete all transformer oil processing, maintenance, and dry-out tasks.

Design Specifications

The SES320(R) insulating oil conditioning and regeneration systems are robustly designed to single pass performance specifications to completely satisfy all possible oil processing requirements.

Mineral Oils

The SES320 is designed to worst case single pass performance standards for mineral oil. The dissolved water saturation level is 90-100 ppm at typical ambient temperatures.

Natural Ester Fluids

The flow capacity of the SES320 must be de-rated by 25% when processing Natural Ester Dielectric Fluids. At least two passes are recommended.

Synthetic Ester Fluids

The flow capacity of the SES320 must be de-rated by 25% when processing Synthetic Ester Dielectric Fluids. At least two passes are recommended.

The SES320 system is a fully customizable solution for any stationary or mobile dielectric fluid conditioning, regeneration, and transformer processing challenge. Numerous vacuum package, heating system, instrumentation, mounting and accessory options allow the SES320 system to be configured to meet your exact requirements.

At the core of the SES320 system, automatic temperature, level, foam, and re-circulation control provides trouble free simple operation for a single operator. Discharge flow rate can be adjusted by simply restricting any discharge valve or from the panel speed control.

Access to all maintenance related components is provided on both stationary and mobile layouts. The mobile version above uses a unique center isle layout scheme.

Support is a phone call away M-F 8-5 EST. After hours call back support can be reached anytime by email.

(260-422-1671)

The SES320 system includes and additional adsorbent treatment stage to remove polar contaminants, and regenerate badly degraded in service mineral oils.

The SES320 system can be configured for simple dedicated oil processing or more demanding single pass evacuated transformer filling. Five vacuum capacity options guarantee you get what you need.

Rotary vane, rotary piston, and dry screw compression roughing pump options are available to meet your specification and price point.

Multiple electric and fuel oil burner primary heating system options are available to accommodate any climate. Secondary heating system options allow oil temperature to be boosted after the degas stage to provide maximum BTU's to the transformer while avoiding oil degradation.

The SES320 system standard control system incorporates a durable NEMA 4 color touch screen operator interface for control, status, alarm annunciation, and data logging. Web based remote monitoring is optional. A legacy switch and pilot light control interface is also available on request.

In addition to the standard process instrumentation, optional instrumentation to continuously monitor and log dissolved moisture, total gas content, ISO cleanliness classification, evacuation dew point, and transformer vacuum are available.

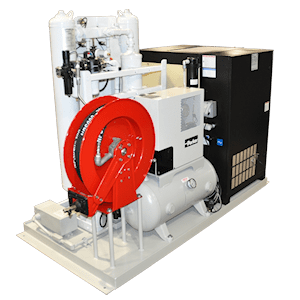

Hose storage reel options include, live reels, storage only reels, manual rewind, electric rewind all available in in three different length capacities.

Mounting options for the SES320(R) system include, stationary skid, deck over axle cargo trailer, box truck, two types of dry vans, and ISO marine shipping containers.

The SES320 system standard control system incorporates a durable NEMA 4 color touch screen operator interface for control, status, alarm annunciation, and data logging. Web based remote monitoring is optional. A legacy switch and pilot light control interface is also available on request.

In addition to the standard process instrumentation, optional instrumentation to continuously monitor and log dissolved moisture, total gas content, ISO cleanliness classification, evacuation dew point, and transformer vacuum are available.

Hose storage reel options include, live reels, storage only reels, manual rewind, electric rewind all available in in three different length capacities.

Mounting options for the SES320 system include, stationary skid, deck over axle cargo trailer, box truck, two types of dry vans, and ISO marine shipping containers.

Inline moisture (ppm) and temperature (°C/°F) monitors are available to provide local display with HMI charting and logging for processor supply and discharge streams. Calibration factors can be changed on the fly for use with mineral, natural, and synthetic ester insulating fluids.

Convectron enhanced pirani vacuum sensors provide provide full scale (760 - 0.01 Torr) digital process pressure display

with HMI charting and logging. Sensors for external vacuum connection and remote transformer monitoring are optional.

An optional processed oil contamination sensor monitors the processed oil stream to provide an ISO cleanliness classification for local digital display with HMI charting and logging.

An optional processed oil Total Gas Content sensor monitors the processed oil stream to provide the oil Total Gas Content for HMI display, charting and logging.

The SES320 system is available in custom skid arrangements for demanding space constrained stationary applications.

The heavy duty Deck Over Cargo (DOC) Trailer accommodates larger SES320 system configurations with plenty of room for to store accessories and protect operators from the elements. See the SES952 Deck Over Cargo Trailer Mounting Configuration work sheet for optional equipment.

Most configurations of the SES320 system can be box truck mounted with room for an ample control area. Chassis axle capacity, frame rails, and wheel base are engineered to accommodate each specific configuration. Chassis from three major manufacturers are available. See the SES953 Box Truck Mounting Configuration work sheet for optional equipment.

Two types and dry van mounting options are available for self powered and shore powered accessory integrated packages. Van mounted packages range from 28'-48' depending on SES320 system configuration, integrated accessories, and amenities. See the SES954 Dry Van Mounting Configuration work sheet for available options.

The SES330 oil processor inlet oil booster pumps allow the SES320 processor to heat and dry the the transformer core by circulating oil through the transformer with the core exposed while under full vacuum. Centrifugal and positive displacement options are available. The popular SES330S centrifugal version is usually in stock.

Vacuum line cold traps are used to measure the rate of water extraction during the evacuation stage of the transformer dry out process. Trailer mounted refrigerated and portable liquid N2 vacuum line traps are available.

The SES330 oil processor inlet oil booster pumps allow the SES320 processor to heat and dry the the transformer core by circulating oil through the transformer with the core exposed while under full vacuum. Centrifugal and positive displacement options are available. The popular SES330S centrifugal version is usually in stock.

Vacuum line cold traps are used to measure the rate of water extraction during the evacuation stage of the transformer dry out process. Trailer mounted refrigerated and portable liquid N2 vacuum line traps are available.

SESCO manufactures two styles of vacuum hose connection manifolds for transformer evacuation. Both styles attach to the standard PRV mounting flange. The SES425-E is for evacuation and allows the PRV to be optionally reattached. The SES425-HOS provides evacuation and directional hot oil spray during evacuated exposed core circulation.

Transformer back fill dry air systems are available for SES320-1800 mobile package integration or as stand alone systems. The systems are available in breathing quality certified and standard dry air quality options. Each type is available in two (-70°) or three (-90°F) stage configurations.

SESCO manufactures two styles of vacuum hose connection manifolds for transformer evacuation. Both styles attach to the standard PRV mounting flange. The SES425-E is for evacuation and allows the PRV to be optionally reattached. The SES425-HOS provides evacuation and directional hot oil spray during evacuated exposed core circulation.

Transformer back fill dry air systems are available for SES320-1800 mobile package integration or as stand alone systems. The systems are available in breathing quality certified and standard dry air quality options. Each type is available in two (-70°) or three (-90°F) stage configurations.

Follow